The Concentricity of our couplings is determined by measuring the total indicated run-out when one end of the coupling is mounted on a shaft known to have “0” run-out and an indicator is placed on the surface of a properly mounted shaft located one inch from the opposite face of the coupling. An indicator on the Face of a properly mounted Stafford collar should show a total run-out or out-of-flat be no more than 0.005″ for small parts and 0.015″ for large parts. The Outer Diameter of both collars and couplings is held to within ☐.015″ of the specified dimension.Īn indicator on the outside diameter of a properly mounted collar should show a total run-out of no more than 0.010″. The Width of our collars is assured to be within ☐.005″ for smaller sizes and ☐.010″ for larger sizes, and the Length of our rigid couplings is held to dimensional tolerances of ☐.015″. The specific tolerances vary depending on size and measure between 0.001″ and 0.005″ over the nominal size. The Inside Diameter (also ID or bore) of our collars and couplings is designed for a smooth slip-fit over industry standard shafts to ensure optimal seating and clamping.

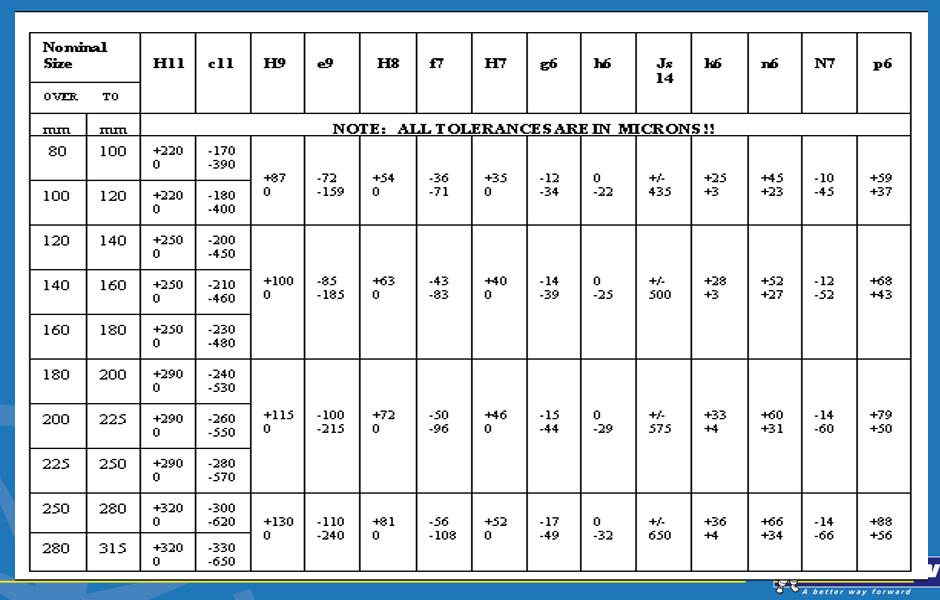

ISO FITS AND TOLERANCES CHART ISO

Our team is capable of providing ultra-precision products to tighter tolerances as needed for specialty applications. Dimensional tolerances for all metric o-rings offered by Global O-Ring and Seal are in accordance with ISO 3601-1B. The charts below gives the Limits and Fits for ISO 286-2 Shaft Basis for holes ranging from 3mm to 400mm and 400mm to 3150mm and Fit Types. The dimensional tolerances described below apply to our standard products. is machined for precision and accuracy to provide unrivaled consistency in fit and function.

On this page we demystify the topic and provide crystal clear information to increase your understanding. Certifications, Registrations & ComplianceĮvery shaft collar and rigid coupling we produce at Stafford Manufacturing Corp. The subject of Limits Fits and Tolerances can sometimes be a little confusing for practising engineers and technicians.What Type of Shaft Collar Should I Use?.Press fitting or the like is required for light alloy members. Permanent assembly, which can not come apart. r5 s6 t6 u6 圆 Firmly coupled together and requires shrinkage press fitting, cold press fitting or forced press fitting. Maintenance, Repair, Retrofit, and Accessories Strong Press Fit, Shrinkage Fit, Freeze Fit Considerable force can be transmitted by the fitting force alone.

0 kommentar(er)

0 kommentar(er)